For heavy lifting and transport Eversafe engineering specializes in applying marine airbags. Eversafe innovative solution can easily solve customers’ problem of heavy lifting and transport when they lack of heavy instruments and in special field. Moreover Eversafe solution can save customers’ most budget and time.

In China Eversafe Engineering transported 1,200 caissons which fabricated for gravity quay and the transportation distance reaches 45 kilometers. This innovative solution make it possible to build caissons near quay in no-special casting yards. Also airbag transportation can conquer the difficulty of caissons embarking semi-submersible barge.

For vessel transportation Eversafe solution makes customers to gain cost-effective and maximized profit. Combining with airbag ship launching technology, people can build vessels on flat ground then move them to the slipway for launching.

Advantages of Eversafe Heavy lifting & transportation solution

Less demand of field

No need of railway and concrete. Only strong enough ground needed

Most less instrument needed

Need no more than air compressors,winches and steel ropes

Environment Protective

No chemical needed.

Time & money saving

Save 60% budget and most time comparing to traditional method

Applicability of airbag heavy lifting & transportation

Weight below 11,000 tonnes

Slope angle below 4 degree

Caisson transport with marine airbags

Caisson structures are widely used in jetty,wharf and levee construction because of their good stability and little underwater construction work. But caissons have to be constructed in special construction factories where there are transport instruments such as trolleys and trials. Building traditional transport instruments is expensive and needs a long construction time. Then in area far from caisson pre-construction factories it comes to be difficult to use caissons for construction. To build temporary construction factories near wanted construction area people need to find an easy caisson transport solution.

The technology of airbag caisson transport and launching is invented to satisfy the eager demand of market. Marine airbags are invented for ship launching initially.The idea of heavy structure transport by airbags is enlightened by airbag ship launching and enabled by the advance of marine airbag's performance. The first airbag caisson transport project was reported in in the year1997 that a 480 tons caisson was moved to a semi-submersible barge by marine airbags in Fujian Shenhu port. Then 500 tons and 900 tons caissons were transported by airbags successfully in the year 2000 and 2003 respectively. In year 2006 the airbag heavy transport technology was successfully applied to move 10 pieces 3500 tons caisson to launch position. The record of most heavy caisson transported by airbags was created by Shenzhen Electric Plant in 2007. They successfully moved 3 pieces 5000 tons caissons to a semi-submersible barge with marine airbags.

To move or launch caisson with airbags has no need of tramroads or heavy jacks, sometimes unpaved ground with suitable slope is acceptable. It is estimated that to transport caissons with marine airbags can save more than 50% investment and total tramroad construction timecomparing to traditional trolley transport method. So this innovative technology is practical and cost-effective.

Caisson lifting

To apply airbag caisson transport technology people should consider to reserve rooms for airbag lifting when fabricate caissons. Generally there are two ways to do it.

1.Trough Method

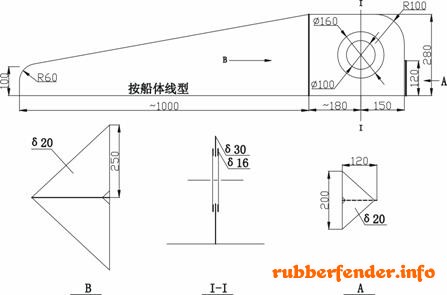

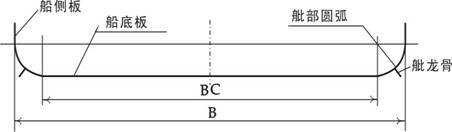

Make lifting troughs when people fabricate the caisson's bottom membrane. The troughs are stuffed with compacted sands during the caisson fabrication period. Before caisson transport, sands in troughs will be flushed out by high pressure water. Then marine airbags can be placed in the troughs to lift caisson. After caisson is lifted transport airbags will be inserted. When transport airbags are pumped to get necessary pressure the lifting airbags will be deflated and removed. The troughs will be stuffed again with blocks then caisson is ready for transport.

2.Girder Structure Method

H type girders are embedded in the caisson bottom membrane with specified spacing and the girder spaces are stuffed with compacted sands. The height of H type girders is between 30-50 centimeters often.When the fabrication of caisson is completed, stuffed sands will be flushed out by high pressure water to make rooms for transport airbags.After airbags are inserted and inflated, H type girders will be removed. Then caisson is ready to be transported.

Caisson Transport

Caisson Transport

Generally caisson transport include the transverse and vertical move. People first move caisson transversely to the vertical move position then place supporting blocks to replace airbags. When airbags are deflated they will be hauled out and relocated vertical to new move direction.

Winches are employed in the marine airbags caisson transport. Winches are used to pull caisson forward and to pull back to stop caisson move. Considering the move stability the working heights of airbags is generally between 40-60 centimeters.

Caisson Launch

To launch caissons, people may move caissons aboard semi-submersible barge or floating dry dock. Also people may launch caisson directly with marine airbags. Move caisson to the sea in low tide then use marine airbags as floating assistant to float caisson in high tide time. When caisson is afloat people can use tugs to drag caissons to the installation position.

The feasibility of using marine airbags to launch caisson directly depends on the caisson parameters, landform and also tide conditions.

Working efficiency of marine airbag caisson transport

Comparing with trolley launch method airbag caisson launch is slow but not so slow. One group people can launch three caissons in two days which can satisfy the construction demand.