1.Range

This standard rules the defining, structure and size,products sign,technique requests,

experimental methods,test rules,marks,packages,shipments and stocks.

This standard is fit for the ballonet made in polyamiale and glues.

2.Citation Standard

The following standard includes the lists which forms this standard list cited.The showing

edition is available when this standard is printed.All the standards can be emended.Each one

will use following newest edition possibly.

GB 527-83 common requests for the physical test method of sulfuration

rubber

GB/T 528-92 measuration for the drawing and extention of sulfuration rubber and

pyrocondensation

GB/T 531-92 test method for the sulfuration rubber Celsius A

rigidily

GB/T 532-89 measuration for the adhere intensity of sulfuration rubber and

weaves

GB 3512-89 test method for the rubber hot air aging

3. Defining

This standard uses following defining

3.1 low-pressure ballonet

working pressure is <0.072/D Mpa ballonet(D is the diameter of ballonet,m)

3.2 middle-pressure ballonet

working pressure is<0.105/D Mpa ballonet(D is the diameter of ballonet,m)

3.3 high-pressure ballonet

woring pressure=or>0.105/D Mpa ballonet(D is the diameter of ballonet,m)

3.4 the body of ballonet

the columniform part of ballonet.

3.5 the port of ballonet

fixing in the both sides for charging and deflating

3.6 the top of ballonet

the subuliform part connecting the body with the port of ballonet.

3.7 working height

the actual height after compressed of startup and loading,

4. Structure and size of the products

4.1 structure form

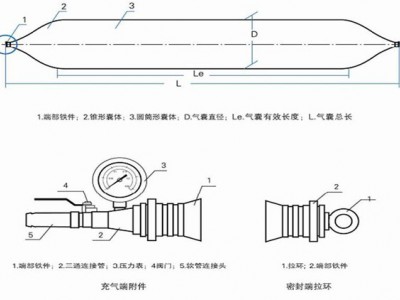

please check the chart 1.

4.2. specification and size

the diameter D has 8 pcs,they are 0.8,1.0,1.2,1.4,1.5,1.6,1.8 and2.0m in all.

1 - ballonet top 2 - ballonet body

3 - ballonet port 4 - safety valve

Ballonet length determined by the actual requests

5. products sign

5.1 signs form

5.2 sign demonstration

diameter is 0.8m,length is5.0m,working pressure is 0.090Mpa:

ballonet 0.8×5.0 0.090

6. technique request

6.1 the capability request for materials

6.1.1 the capability of polyamiale cloth

6.1.1.1 polyamiale cloth 1260D2V1

6.1.1.2 polyamiale cloth reputure intensity=or>205.8n/pcs

6.1.2 rubber physical mechanism capability

6.1.2.1 the capability please check the form 1.

6.2 technique parameter

technique parameter of working pressure,working height,carrying capacity/meter for all

kinds of low-pressure,middle-pressure,high-pressure for diameters,please check the form 3.

6.3 capability request

6.3.1 size warp

(please check the form4)

6.3.2 elasticity distortion quantity

when using 1.2 times working pressure to test pressures,diameter<or=5%.

6.3.3 safety modulus

safety modulus=or>4.5

6.3.4 air density

charging 1h,pressure falling<or=5%.

6.3.5 appearance request

linetype smooth,no crackle or air bubble,skinny,interfused impurity,clear dirt and other

appearance faulty.

6.3.6 safety charging device

ballonet port should be fixed safery valve which bounce pressure is

the 1.25 times than the working pressure.

7. testing method

7.1 testing method for materials

7.1.1 the measuration for the rubber drawing and extention and the rate of snap and elongation.

according to the test of GB 527,GB/T 528,the result should fit for the request of form 1.

7.1.2 rubber rigidity testing

according to the test of GB/T531,the result should fit for the request form 1.

7.1.3 rubber hot air aging testing

according to the test of GB 3512,the result should be the request form 2.

7.1.4 adhere internsity for sulfuration rnbber and the polyamile cloth testing

accorging to GB/T 532 testing,the result should be request form 1.

7.2 products size warp and distortion measurment

7.2.1 size warp measurment

when ballonet charges and waters,and the pressure reaches the working pressure,

measured by the tapeline of diagragh 1 mm,the warp should be request form 4.

7.2.2 elasticity testing

when ballonet charges and waters ,and pressure reaches the used pressure on the

form 3 is 1.2 times ,measured by the tapeline of diagragh 1mm.the perimeter is c,the formula

is as followings :

d=c/-D'..............................................................(1)

d diameter elasticity

c perimeter

D' actual diameter under working pressure

7.3 testing the working pressure by demolish

7.3.1 for testing

diameter is 0.6m,length is >1.8m,material,structure ,technics are the same with

products ballonet .

Also can use other ballonet as testing ,but the length must >3 times than the diameter.

material,structure,technics are the same with the products ballonet.

7.3.2 testing temperature

-10-40 degrees

7.3.3 testing apparatus

1.5 grades pressure gauge

7.3.4 testing method air carrying charging demolish

7.3.5 demolish pressure average

7.3.5.1 under the temperature are the same,do the 3 pcs ballonets demolish,

the formula is :

P=p1+p2+p3/3............................................................(2)

P1,p2,p3 are the first,second ,third ballonet demolish pressure,Mpa.

7.3.5.2 P should be=or >4.5 times than the pressure on the form 3

7.3.5.3 the testing for the ballonet pressure

the formula is

Pe=D1P/Nd..................................................................(3)

Pe is working pressure

P is demolish testing pressure average

D1 is ballonet body diameter

D is ballonet dianmeter

n is safety modulus

7.4 working pressure testing

after charging ,and pressure reaches the 1.5 Pe,keeping 10 min,pressure falling

should <2%

7.5 air density testingwhen charging ,and pressure reaches the Pe,after 1h should reach for the 6.3.4.

7.6 others

testing apparatus,tools,equipments should be proved regular.the precision should be

the request for the objects tested.

8. testing rules

8.1 the testing divided into leaving factory testing and type testing .testing item and

technique request should process for the form 5.

8.2 Every products should test leaving factory by manufacture technique testing

department,and show the certification.

8.3 Should do type testing as followings

a. before putting into production

b. when materials changes

c. when structure changes

d. when the technics of impacting capacibility

e. producting every other two years

f. reproducing after stopping production for 6 months

g. customers request

h. national quality superviser testing department requests

9. sign,packages,shipments and stocks

9.1 sign

9.1.1 every ballonet should have the certifications for the seals by manufacture technique

testing departmentand specification for the use and vindicate.

9.1.2 products sign range as followings

a. product name

b. type

c. specification

d. products serial number

e. working pressure

f. weight

g. manufacture name

h. leaving date

9.2 packages

pack by plastic weave bags after fold

9.3 shipments

short carrying should swing,uplift,rolling carrying with charging.not to haul on the ground

Long shipments should underlay well and fix it well

9.4 stocks

9.4.1 if ballonet doesn't be used for long time, it should be washed clearly,airinged,charged

inside and besmeared smooth gesso outside,abd put into room to dry, cool and aeration.

9.4.2 the place where stock ballonet should far away from hot resource

9.4.3 ballonet can't be contacted with acid, alkali,grease and organic impregnant.

9.4.4 ballonet should be put flatly and extension when it doesn't be used,not to pile up,or pile

some heavy things up on.